Advanced Manufacturing

In the rapidly evolving landscape of modern manufacturing, lasers have become a transformative technology, revolutionizing processes across various industries. From precision cutting and welding to microfabrication and additive manufacturing, nLIGHT lasers provide unmatched accuracy, speed, and reliability. Our laser technology is essential for enhancing productivity, reducing waste, and unlocking new possibilities for innovation. Every day, we discover advancements that bolster the future potential of lasers in shaping the manufacturing world. At nLIGHT, we’re not only changing how things are made; we’re changing the things that can be made.

Additive Manufacturing

nLIGHT additive is expanding the addressable markets for metal additive manufacturing. Engineered specifically for modern powder bed fusion equipment, nLIGHT lasers simplify the user experience, accelerate print speeds with high yield, and profoundly improve the affordability of simple to complex parts. Driven by a culture of deep collaboration with its customers, nLIGHT integrates advanced laser and software technology into production-certified metal printers that serve a broad range of aerospace, defense and automotive applications.

nLIGHT’s Corona® AFX® lasers are the first industrially-robust and economically viable beam shaping lasers developed, and remain the only laser on the market capable of switching between high-resolution “singlemode” output and high-productivity, process-stabilizing ring beams. Backed by over 30 patents, nLIGHT’s lasers are already deployed in commercial printers, from single-format to large-format multi-AFX® platforms, and are finally delivering the productivity and quality required to drive part costs down to open new markets. Considering the productivity economics and metallurgical benefits, dynamic beam shaping lasers from nLIGHT are poised to become the new standard for metal additive manufacturing.

Redefining Metal Additive Manufacturing with Dynamic Beam Shaping

Pioneering the Future of Laser-Based Manufacturing

nLIGHT is transforming metal Additive Manufacturing (AM) with cutting-edge dynamic beam shaping technology. Engineered to push the boundaries of Powder Bed Fusion-Laser Beam (PBF-LB) printing, nLIGHT’s high-power fiber lasers enhance speed, stability, and cost efficiency—opening new possibilities for aerospace, defense, and industrial applications.

Corona® AFX®: The Industry’s First Dynamic Beam Shaping Laser

nLIGHT’s Corona® AFX® laser is the first industrial-grade beam shaping laser that dynamically switches between high-resolution single-mode output and high-productivity ring beams. This patented breakthrough delivers:

● Faster Print Speeds – Increased hatch spacing and layer thickness reduce build times.

● Higher Quality Parts – Adaptive beam shaping improves melt pool stability and metallurgical properties.

● Lower Production Costs – Productivity gains rival conventional manufacturing methods like forging and CNC machining.

Unlocking Productivity Beyond Traditional AM

While AM machine manufacturers previously relied on more lasers to boost efficiency, nLIGHT takes a different approach: beam-shaping lasers. By adjusting power density and spot size in real time, dynamic beam shaping eliminates inefficiencies associated with Gaussian beam profiles—resulting in precise, repeatable, and scalable AM production.

Industry Validation & Global Adoption

nLIGHT’s technology is driving the next generation of additive manufacturing systems, with adoption by industry leaders such as EOS, DMG Mori, AMCM, and Aconity3D. Key benefits include:

● 82% reduction in build time for complex turbine blades (Aconity3D).

● 75% reduction in spatter and soot, leading to cleaner builds and longer filter life (Fraunhofer IAPT).

● 2-6x cost savings per part compared to standard AM systems (DMG MORI USA).

● Best in-class reproducibility of rocket engine parts compared to other AM systems (the leading space launch and hypersonic engine providers).

Shaping the Future of Additive Manufacturing

nLIGHT’s Corona® AFX® lasers are the foundation for the next generation of AM—delivering unprecedented productivity, reliability, and material flexibility. With a roadmap towards 2kW+ fiber lasers, nLIGHT is redefining what's possible in high-performance metal printing.

nLIGHT is shaping the future—one layer at a time.

Welding

nLIGHT fiber lasers enabling new electric vehicles.

The all-new nLIGHT welding family integrates an optional fiber coupler or 2- or 4-channel beam switch with a high-power fiber laser. Durable and versatile, this laser was designed with trusted and durable components for high productivity solutions in welding, cladding, heat treating, brazing and other materials processing applications. Based on nearly two decades of high-power laser innovation, this fiber laser features the latest in optical technology, allowing for exceptional process range and, consistent part quality. Ergonomically designed to be simple and easy to use for quick fiber replacements and increased uptime.

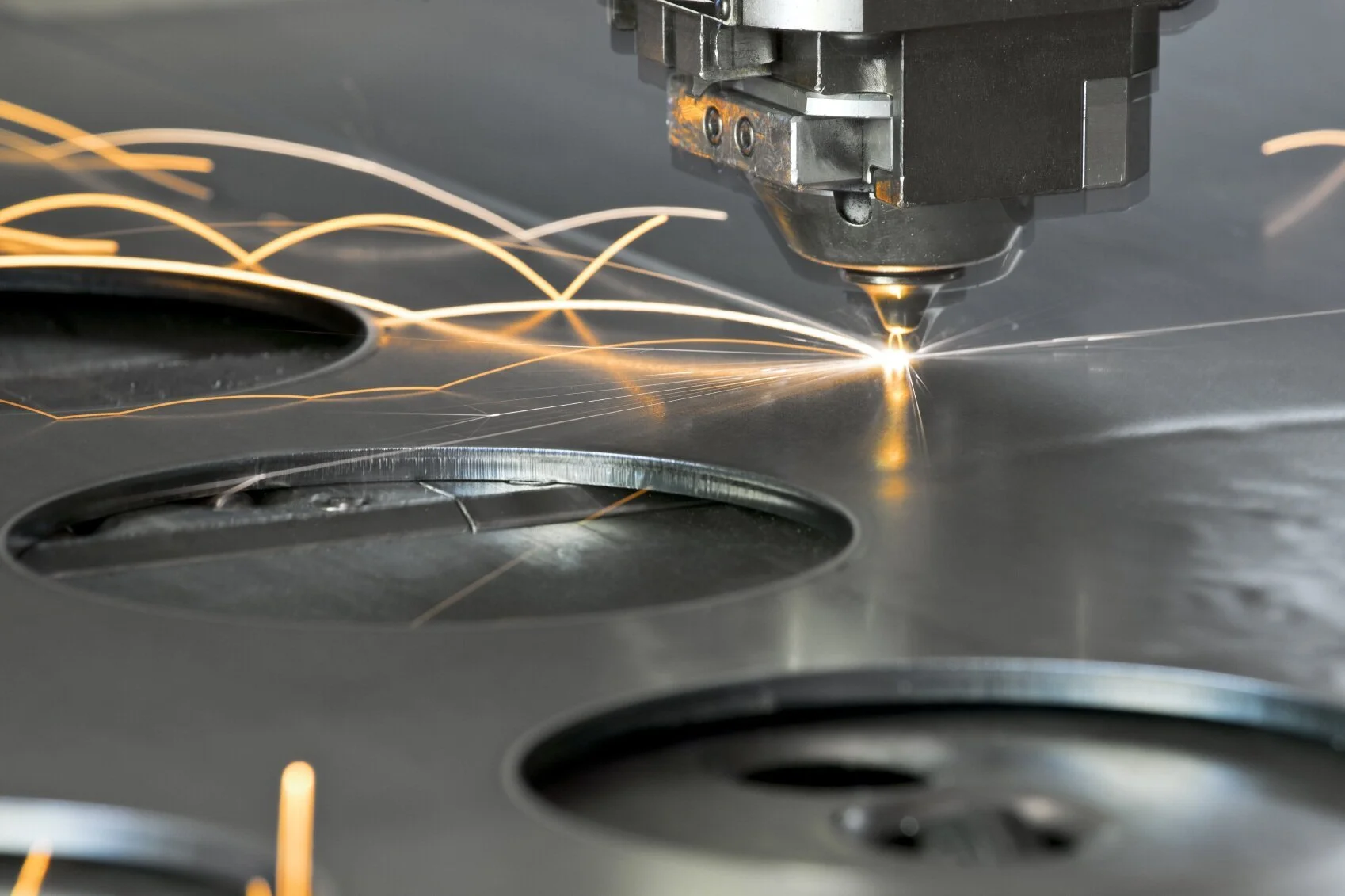

Metal Cutting

Our fiber lasers with advanced metal processing technology provide tunable beam quality with an all-fiber design. This award-winning product line allows the machine operator to tune the laser spot size, divergence, and beam shape to best suit their application. The versatile palette of beam settings enables processing of all metals without compromise. In cutting, these fiber lasers provide CO2-like edge quality for thick metal and the speed advantages of fiber lasers for thin metal—all with the reliability and low cost of ownership of fiber lasers.